Spargers & Gas Diffusers for Lab & Diagnostic Applications

Spargers and diffusers are widely used across a range of industries due to their ability to introduce gases into liquids in a controlled and efficient manner. They can be found in the semiconductor and microelectronics sector, environmental remediation, aquaculture, chemical processing, food and beverage processing, and wastewater treatment. But they are also widely used in the biotech and pharma environments, as well as in diagnostics and lab systems. Because the ADLM Conference focuses on the latter areas, this blog will focus on diffuser and sparger applications in lab and diagnostic applications, and delve just briefly into bioprocessing and biotech applications.

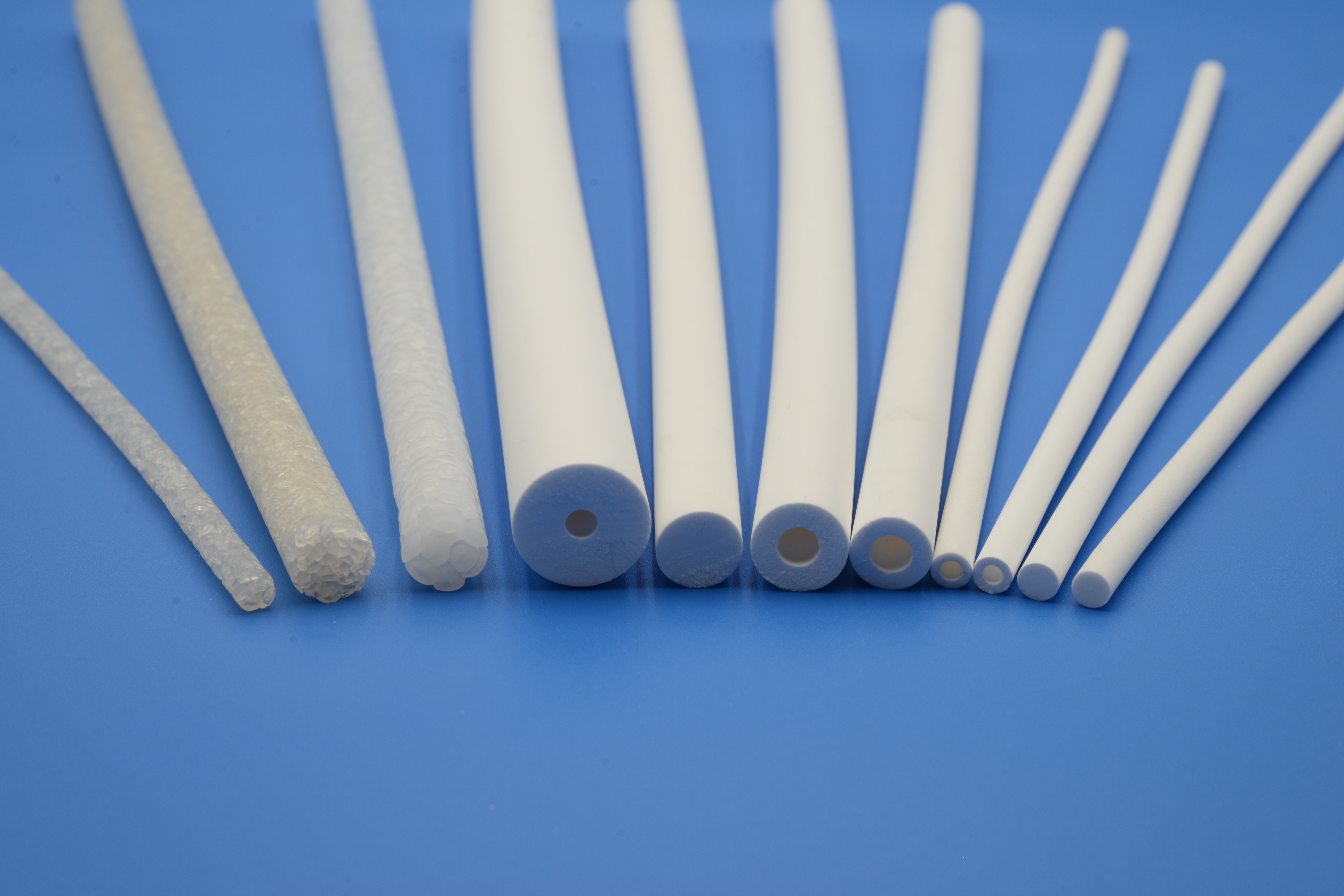

Though often grouped together, spargers and gas diffusers serve distinct functions, depending on the application.

Defining the Difference

A sparger is a device that typically injects gas into a liquid through a network of holes, slots, or porous media, creating relatively large bubbles. This promotes aggressive mixing and is valuable where high flow rates and mass transfer are needed.

A gas diffuser, in contrast, uses finely porous materials to create small, consistent bubbles with high surface-area contact. The result is gentler, more controlled gas-liquid interaction, ideal for processes requiring subtle aeration or where contamination and turbulence must be minimized.

While both facilitate gas transfer, spargers prioritize throughput and agitation, whereas diffusers focus on precision and uniformity.

Challenges in the Lab

Laboratory systems and instruments require precise control over gas-liquid interactions and uniform fluid distribution to support critical processes. These needs include effective aeration for cell cultures, consistent reagent mixing for assay accuracy, and reliable purging to prevent contamination or oxidation. Reproducible reactions and fluidic stability are essential for experimental integrity and diagnostic reliability.

Spargers in Laboratory Applications

Spargers are used to introduce gases into liquids, typically for aeration, mixing, or gas-liquid reactions. In bioreactors and fermentation setups, spargers deliver oxygen or carbon dioxide to support microbial or cell growth. Their fine pore structure ensures efficient gas dispersion, which enhances mass transfer rates. They are also employed in chemical synthesis labs for stripping volatile compounds or purging solutions with inert gases (like nitrogen) to prevent oxidation.

Diffusers in Laboratory Applications

Diffusers help distribute gases or liquids uniformly within a system. In analytical chemistry, they aid in mixing reagents or dispersing solvents. Their role is often passive but critical for ensuring homogeneity and reproducibility in experiments, especially in fluidic systems or automated platforms. In water testing or environmental labs, air diffusers are used for aeration in bench-scale treatment setups.

Challenges in Diagnostics

Diagnostic systems require precise control of microfluidic flows, consistent reagent mixing, and bubble-free environments to ensure reliable assay performance. These needs include maintaining laminar flow for accurate signal detection, preventing air entrapment that could disrupt fluid paths, and enabling gentle mixing during sample preparation without mechanical agitation. Such functionality is critical in blood analysis platforms, lab-on-a-chip systems, and cartridge-based diagnostics where fluid stability and reproducibility directly impact test sensitivity and accuracy.

Spargers in Diagnostic Applications

In diagnostics, spargers are used in reagent preparation and bioproduction. For example, spargers find niche use in sample preparation stages where fluid mixing is required without mechanical agitation. Spargers are also used in the manufacture of antibodies or enzymes used in assays, or to oxygenate culture media in bioreactors. They may also be used to purge diagnostic fluids with inert gases to stabilize sensitive components. Their ability to generate fine bubbles ensures consistent gas-liquid interaction, which is vital for maintaining reagent quality.

Diffusers in Diagnostic Applications

In diagnostic systems—from blood analysis platforms to lab-on-a-chip devices—gas diffusers play a key role in regulating microfluidic flow and preventing bubble formation that could interfere with assay performance. Their ability to maintain clean, laminar flow is essential for sensitive readouts. Diffusers also support uniform mixing and fluid distribution in cartridge-based systems, ensuring consistent interaction between reagents and samples. In lateral flow assays and microfluidic platforms, porous plastic diffusers help control flow rates, prevent channeling, and enable sterile gas exchange in sealed environments.

Bioprocessing & Biotech Apps

Beyond all this, spargers and diffusers are often found in various biotech applications. In bioreactors, spargers deliver oxygen or CO₂ for cell culture aeration. Their ability to saturate fluid volumes ensures robust growth conditions—although care must be taken to avoid shear stress. And in fermentation tanks, spargers provide needed oxygen to microbial cultures, while diffusers maintain dissolved oxygen levels for downstream purification and metabolite control. Diffusers also serve roles in delicate processes such as stem cell cultivation or enzymatic reactions, offering gentler gas introduction to preserve cellular structures.

Summary

Whether delivering oxygen or other gases, nurturing stem cells, or protecting patient safety, spargers and gas diffusers quietly uphold the demanding standards of critical applications. Understanding their distinct roles and tailoring materials and designs can dramatically enhance performance and reliability in each environment.

Though often grouped together, spargers and gas diffusers serve distinct functions, depending on the application.

Defining the Difference

A sparger is a device that typically injects gas into a liquid through a network of holes, slots, or porous media, creating relatively large bubbles. This promotes aggressive mixing and is valuable where high flow rates and mass transfer are needed.

A gas diffuser, in contrast, uses finely porous materials to create small, consistent bubbles with high surface-area contact. The result is gentler, more controlled gas-liquid interaction, ideal for processes requiring subtle aeration or where contamination and turbulence must be minimized.

While both facilitate gas transfer, spargers prioritize throughput and agitation, whereas diffusers focus on precision and uniformity.

Challenges in the Lab

Laboratory systems and instruments require precise control over gas-liquid interactions and uniform fluid distribution to support critical processes. These needs include effective aeration for cell cultures, consistent reagent mixing for assay accuracy, and reliable purging to prevent contamination or oxidation. Reproducible reactions and fluidic stability are essential for experimental integrity and diagnostic reliability.

Spargers in Laboratory Applications

Spargers are used to introduce gases into liquids, typically for aeration, mixing, or gas-liquid reactions. In bioreactors and fermentation setups, spargers deliver oxygen or carbon dioxide to support microbial or cell growth. Their fine pore structure ensures efficient gas dispersion, which enhances mass transfer rates. They are also employed in chemical synthesis labs for stripping volatile compounds or purging solutions with inert gases (like nitrogen) to prevent oxidation.

Diffusers in Laboratory Applications

Diffusers help distribute gases or liquids uniformly within a system. In analytical chemistry, they aid in mixing reagents or dispersing solvents. Their role is often passive but critical for ensuring homogeneity and reproducibility in experiments, especially in fluidic systems or automated platforms. In water testing or environmental labs, air diffusers are used for aeration in bench-scale treatment setups.

Challenges in Diagnostics

Diagnostic systems require precise control of microfluidic flows, consistent reagent mixing, and bubble-free environments to ensure reliable assay performance. These needs include maintaining laminar flow for accurate signal detection, preventing air entrapment that could disrupt fluid paths, and enabling gentle mixing during sample preparation without mechanical agitation. Such functionality is critical in blood analysis platforms, lab-on-a-chip systems, and cartridge-based diagnostics where fluid stability and reproducibility directly impact test sensitivity and accuracy.

Spargers in Diagnostic Applications

In diagnostics, spargers are used in reagent preparation and bioproduction. For example, spargers find niche use in sample preparation stages where fluid mixing is required without mechanical agitation. Spargers are also used in the manufacture of antibodies or enzymes used in assays, or to oxygenate culture media in bioreactors. They may also be used to purge diagnostic fluids with inert gases to stabilize sensitive components. Their ability to generate fine bubbles ensures consistent gas-liquid interaction, which is vital for maintaining reagent quality.

Diffusers in Diagnostic Applications

In diagnostic systems—from blood analysis platforms to lab-on-a-chip devices—gas diffusers play a key role in regulating microfluidic flow and preventing bubble formation that could interfere with assay performance. Their ability to maintain clean, laminar flow is essential for sensitive readouts. Diffusers also support uniform mixing and fluid distribution in cartridge-based systems, ensuring consistent interaction between reagents and samples. In lateral flow assays and microfluidic platforms, porous plastic diffusers help control flow rates, prevent channeling, and enable sterile gas exchange in sealed environments.

Bioprocessing & Biotech Apps

Beyond all this, spargers and diffusers are often found in various biotech applications. In bioreactors, spargers deliver oxygen or CO₂ for cell culture aeration. Their ability to saturate fluid volumes ensures robust growth conditions—although care must be taken to avoid shear stress. And in fermentation tanks, spargers provide needed oxygen to microbial cultures, while diffusers maintain dissolved oxygen levels for downstream purification and metabolite control. Diffusers also serve roles in delicate processes such as stem cell cultivation or enzymatic reactions, offering gentler gas introduction to preserve cellular structures.

Summary

Whether delivering oxygen or other gases, nurturing stem cells, or protecting patient safety, spargers and gas diffusers quietly uphold the demanding standards of critical applications. Understanding their distinct roles and tailoring materials and designs can dramatically enhance performance and reliability in each environment.

Category Press Releases