Sealing the Deal

Shutoffs & Self-Sealing Filters for Lab Diagnostics

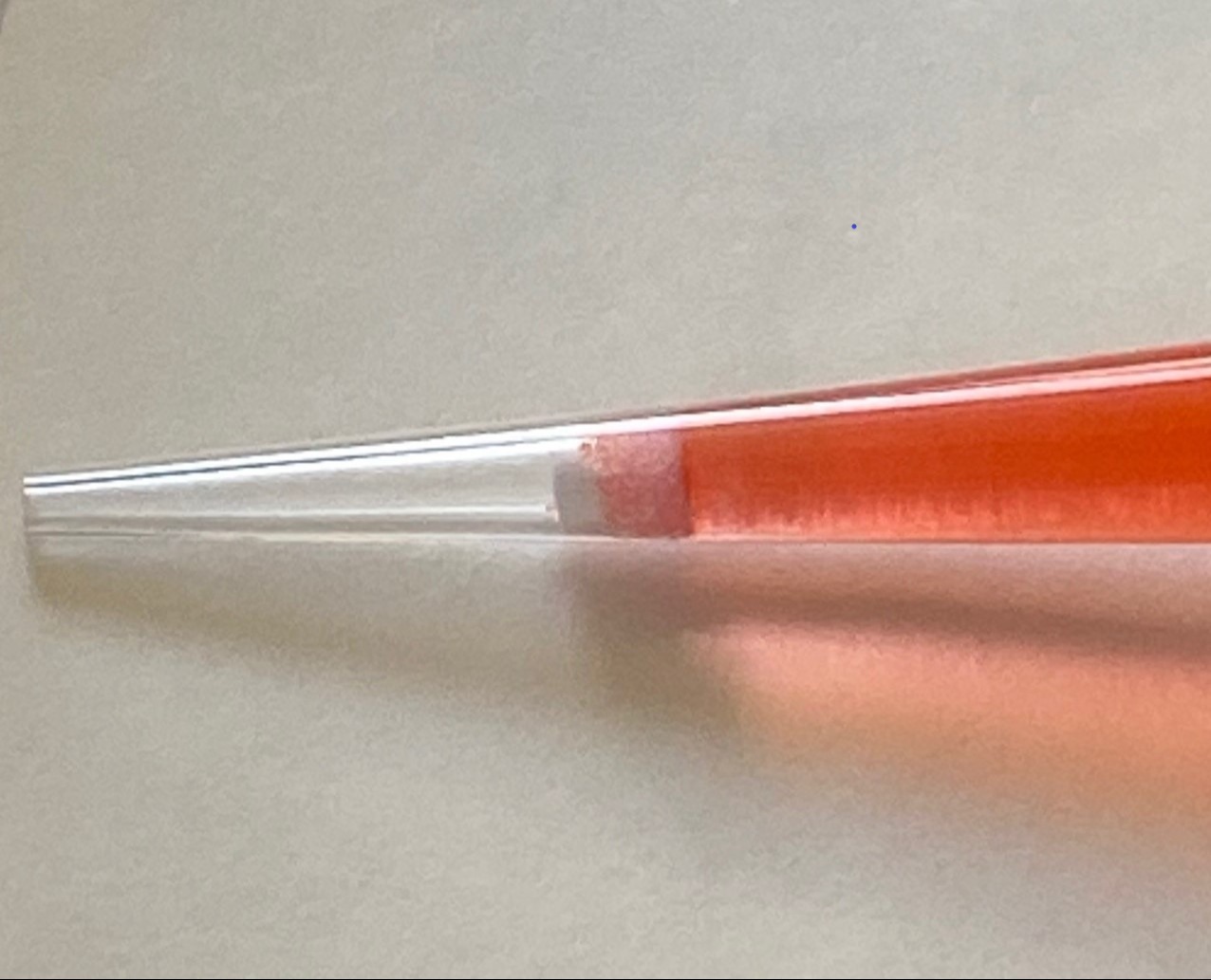

Shutoff filters and self-sealing filters play a critical role in laboratory and clinical diagnostics by preventing unwanted fluid flow and potential contamination. These filters are designed to automatically stop fluid movement and the possible entry of contaminants when certain conditions are met, such as excessive (or negligible) pressure or the presence (or absence) of liquid.

Applications

Shutoff filters and self-sealing filters made from sintered porous plastics are widely used in various labs and clinical diagnostic applications. These include:

Key Considerations for Use

When selecting shutoff filters for laboratory and clinical applications, several factors should be considered:

Shutoff filters are essential components in laboratory and clinical diagnostics, ensuring precise fluid control, contamination prevention, and equipment protection. Whether in microfluidics, lab instrumentation, or medical devices, these filters enhance reliability and efficiency in diagnostic workflows. Understanding their function and selecting the right filter for specific applications can significantly improve laboratory operations and patient outcomes.

Note: A commonly asked question is whether shutoff filters are the same as self-sealing filters. While both serve to control fluid movement, self-sealing filters typically contain hydrophobic or oleophobic media that block liquid passage upon contact, whereas shutoff filters may use mechanical or chemical mechanisms to halt flows. The distinction lies in their activation method: self-sealing filters rely on material properties, while shutoff filters may incorporate valves, pressure-sensitive components, or chemical mechanisms. However, many in the MedTech and biotech sectors tend to use the terms interchangeably, as hydrophobic or oleophobic media blended with other materials can incorporate chemical mechanisms to stop flows – which (according to the definition above) can render a self-sealing filter a shut-off filter and thereby blur the distinctions noted.

Shutoff filters and self-sealing filters play a critical role in laboratory and clinical diagnostics by preventing unwanted fluid flow and potential contamination. These filters are designed to automatically stop fluid movement and the possible entry of contaminants when certain conditions are met, such as excessive (or negligible) pressure or the presence (or absence) of liquid.

Applications

Shutoff filters and self-sealing filters made from sintered porous plastics are widely used in various labs and clinical diagnostic applications. These include:

- Microfluidics

In microfluidic devices, shutoff filters help regulate fluid movement within lab-on-a-chip systems. These filters ensure precise control over sample and reagent flow, preventing cross-contamination and ensuring accurate test results. Their ability to automatically stop flow when necessary makes them ideal for automated diagnostic assays. In PCR and DNA sequencing platforms, these filters help maintain precise liquid handling in genetic analysis applications.

- Lab Instrumentation

Shutoff filters are also integrated into high-purity liquid systems used in clinical analyzers. These filters prevent backflow and contamination, ensuring that diagnostic instruments receive consistent, high-quality water for accurate testing. In gas chromatography and mass spectrometry, shutoff filters help maintain clean gas flows, preventing impurities from affecting analytical results.

- Diagnostic and Medical Equipment

In clinical settings, shutoff filters are used in blood and urine analyzers, IV lines, and dialysis machines to prevent fluid or sample contamination, absorb excess liquid, maintain pressure balance, prevent air bubbles from disrupting sample analysis, and ensure patient safety. Their ability to automatically seal off when fluid is present (or absent) helps prevent air embolisms, improves operational reliability, and ensures accurate test results.

Key Considerations for Use

When selecting shutoff filters for laboratory and clinical applications, several factors should be considered:

- Material Compatibility: Ensure the filter material is compatible with the fluids being processed, whether biological samples, reagents, or gases.

- Flow Rate and Pressure Sensitivity: Choose filters that match the required flow rate and pressure conditions to prevent unintended shutoff or leakage.

- Sterilization and Maintenance: Some shutoff filters must withstand autoclaving, gamma irradiation, or chemical sterilization to maintain sterility in life sciences applications.

- Integration with Equipment: Filters should be easily replaceable and compatible with existing lab instrumentation to minimize downtime and maintenance costs.

Shutoff filters are essential components in laboratory and clinical diagnostics, ensuring precise fluid control, contamination prevention, and equipment protection. Whether in microfluidics, lab instrumentation, or medical devices, these filters enhance reliability and efficiency in diagnostic workflows. Understanding their function and selecting the right filter for specific applications can significantly improve laboratory operations and patient outcomes.

Note: A commonly asked question is whether shutoff filters are the same as self-sealing filters. While both serve to control fluid movement, self-sealing filters typically contain hydrophobic or oleophobic media that block liquid passage upon contact, whereas shutoff filters may use mechanical or chemical mechanisms to halt flows. The distinction lies in their activation method: self-sealing filters rely on material properties, while shutoff filters may incorporate valves, pressure-sensitive components, or chemical mechanisms. However, many in the MedTech and biotech sectors tend to use the terms interchangeably, as hydrophobic or oleophobic media blended with other materials can incorporate chemical mechanisms to stop flows – which (according to the definition above) can render a self-sealing filter a shut-off filter and thereby blur the distinctions noted.

Category Press Releases